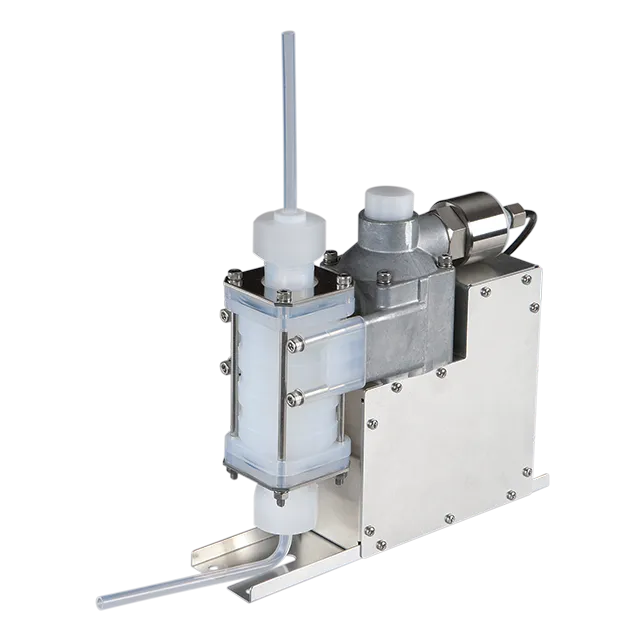

Features of PDS-105R

Substantial Saving of Resist

The use of a high-torque stepper motor as the drive source results in a consistent discharge volume, unimpeded by filter clogging or viscosity change. A repeatable accuracy (0.3%) of discharge is maintained.

• Discharge precision: ±0.3% (F.S.)

• Linearity: ±0.5% (F.S.)

• Resolution: 0.01 mL

Contamination Free

The pump portion is of tubephragm structure wetted internals are flat and smooth, with a small dead volume. Because the system hardly has a place that allows liquid resist to dwell, production of particles is prevented.

Usable for a Variety of Coating Processes

Since the discharge velocity can be changed freely in a shot, the system is capable of dealing with a variety of resist coating processes including application of a very small amount or in a very short period of time.

Reduction of Downtime

A discharge amount and a discharge time can be set only by entering values in the controller. It can save operator’s time and labor and reduce downtime.

Specifications

| Max. discharge capacity | 5.0 mL/shot |

|---|---|

| Discharge speed | 0.1 – 4.0 mL/sec |

| Suction speed | 0.1 – 3.0 mL/sec |

| Max. discharge pressure | 0.15 MPa |

| Discharge precision | ±0.3% (F.S.) |

| Main materials | PFA, PTFE |

| Max. liquid viscosity | 200 mPa·s |

• Above specification may changed by installation, handling liquid, etc. For detail, please contact us.

Đánh giá Tubephragm dispensing pump PDS-105R

Chưa có đánh giá nào.